MAINTENANCE AND CLEANING OF COMMERCIAL KITCHEN HOODS

Our cleaning and maintenance services meet applicable standards and

IKECA - Certification

For more than 15 years

Cadexair is an active member of the IKECA trade association. This organization ensures that its members carry out their work in strict compliance with Canadian codes and standards.

IKECA is an international trade association founded in 1989 to meet the NFPA96 (National Fire Protection Association) standard. Commercial kitchen ventilation systems must be inspected and cleaned by certified individuals or organizations. All IKECA members are required to hold a competency card that is only given after continuing education training and rigorous examinations.

We offer Various Maintenance Programs Tailored to Your Needs:

- Maintenance program for self-cleaning range hood systems, including monthly visits and required biotech products

- Filter replacement program for air purification systems and air supply fans, based on your needs

- Monthly cleaning program for hood filters

- Fan belt replacement and bearing maintenance program

- Grease trap treatment program, including supply of biotech solvent products

Types of interventions

We offer maintenance programs tailored to your type and volume of cooking that meet applicable standards.

Preventive Inspections and Maintenance

Inspection of commercial kitchen ventilation systems by a competent and certified company is mandatory according to applicable NFPA96 standard, article 11.4.

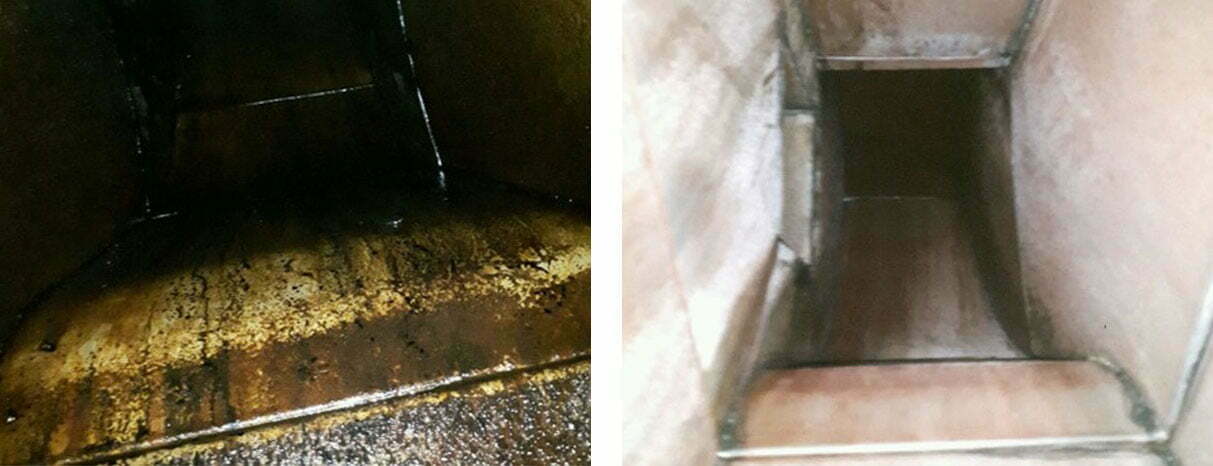

Cleaning the Systems

Grease build-up in commercial hood systems must be cleaned by a company with the proper training, in accordance with section 11.6.1 of the current NFPA 96 standard.

Engineering Support

Some systems are more advanced technologically and need a more complex understanding. That is why all our technicians have access to our team of engineers who design this type of ventilation system.

Technical Support

Your system is not working? You have a problem? Our technical support teams are there to help you!

Several reasons to choose Cadexair

Qualified personnel with continuing education programs

Over 30 years of expertise

Several teams across the province

IKECA certified and trained

Contractor Check accreditation

Compliant with currents standards

Personnel with access to an engineering department

Personnel qualification: Confined space training

Personnel qualification: Working at heights training

Our technicians meet the most stringent safety standards in the industry

Cadexair employees are authorized to work in several restricted-access areas

Personnel qualification: WHMIS training

Personnel qualification: Lockout training

We Offer Several Maintenance Programs Tailored to Your Needs

The Quebec Construction Code refers to the NFPA96 2011 standard to regulate the construction and maintenance of air ventilation systems for commercial kitchens. Competent authorities, including fire protection services and insurers, are mandated to apply this standard.

Articles on the Maintenance of Ventilation Systems

11.4* Inspection for accumulation of grease. The complete exhaust system must be inspected by a competent company or person(s) with appropriate training and certification recognized by the authorities having jurisdiction, in accordance with the table below.

| Type or Volume of Cooking | Frequency |

|---|---|

| Systems serving solid fuel cooking operations | Monthly |

| Systems serving high-volume cooking operations, such as 24-hour cooking, charbroiling, or wok cooking | Quaterly |

| Systems serving moderate-volume cooking operations | Semi-annual |

| Systems serving low-volume cooking operations, such as churches, day camps, seasonal business, or seniors homes | Annual |

11.6.1* Following the inspection, the section of the exhaust system contaminated by grease deposits must be cleaned by a competent company or person(s) with appropriate training and certification recognized by the authorities having jurisdiction.

When to Clean

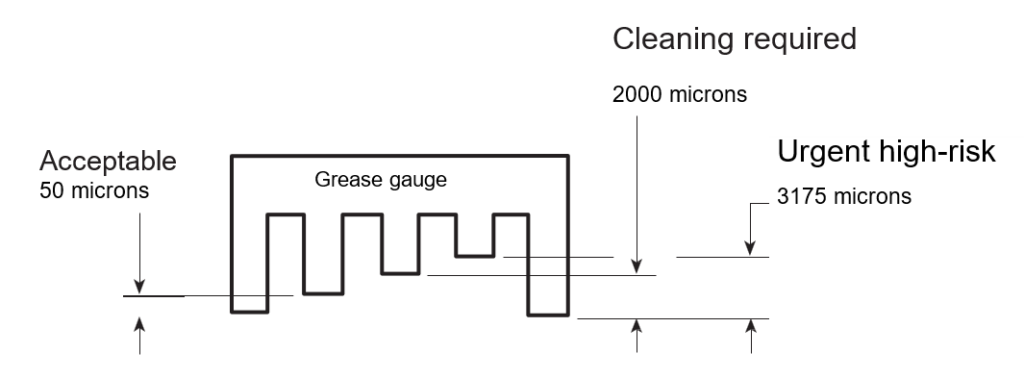

In accordance with NFPA96, a grease deposit gauge system is installed to notify when cleaning is necessary. The level is measured with a grease depth comb, shown here, which is scraped along the surface of the horizontal and/or vertical duct. A measured depth of 2000 microns (0.078 inch) indicates that cleaning is required to eliminate the risk of fire. The grease comb also includes a measuring point to indicate the high-risk zone, which is 3175 microns (0.125 inch). If the grease reaches this level, the 16-gauge galvanized steel ducts will not be able to withstand the heat produced by a fire and will open up, allowing the fire to spread freely.

Technical Support

Call Cadexair for Advanced Technical Support

You can count on a customer service experience that is focused on what you need and ensures a professional service, carried out by experienced personnel for:

- Belt replacement

- Motor replacement

- Replacement of electronic controls

- Replacement of components for variable-flow hoods

- Upgrades to the control system

- Exhaust air or smoke problems

Cadexair serves various clients such as:

Thousands of other kitchen professionals around the world have chosen Cadexair technology

Free Online Customer Access

QUOTES

We offer maintenance programs tailored to your type and volume of cooking that meet applicable standards