Amidst the sizzle and chatter of New York City’s diverse culinary venues, a significant transformation is underway, influenced by critical environmental considerations.

Recent enhancements to New York’s air pollution control laws, specifically chapters 37 and 38, mandate stringent measures for commercial kitchens. These laws compel the installation of effective emission control devices in kitchens, particularly those that significantly contribute to urban air pollution.

Air purification technologies such as the electrostatic precipitator and Cadexair’s innovative Stadium hood are leading solutions helping kitchens meet these requirements while promoting safer, cleaner dining environments.

In-Depth Exploration of Local Law Chapters 37 and 38

New York City’s Local Law chapters 37 and 38 are critical components in the city’s effort to enhance environmental standards. These regulations explicitly target emissions from commercial kitchens. They are pivotal for maintaining air quality and public health, particularly in urban areas with dense populations and significant commercial food preparation activities.

Local Law 37: Comprehensive Emission Control for Commercial Charbroilers

Local Law 37 focuses on controlling emissions from commercial kitchens, setting strict guidelines for installing and maintaining exhaust systems that effectively reduce grease, smoke, and particulate matter emissions. This law aims to align New York City’s standards with broader environmental health goals, reducing the public health risks associated with poor air quality.

This law sets stringent requirements for commercial kitchens, particularly those using chain-driven or under-fired commercial charbroilers that cook more than 875 pounds of meat per week. To mitigate the high levels of particulate matter (PM10) emitted by these operations, the law mandates the installation of effective emission control devices:

- Emission Reduction Requirements: Each charbroiler must have an emission control device that achieves at least a 75% reduction in PM10 emissions. A flameless catalytic oxidizer or equivalent device is required for chain-driven broilers, while under-fired broilers can utilize an electrostatic precipitator (ESP) or similar technologies.

- Certification and Compliance: Devices must be tested and certified according to specific standards detailed in sections 37-05 and 37-06 of the regulation, ensuring they effectively reduce emissions as required.

Local Law 38: Establishing Standards for New Cook Stoves

Local Law 38 complements these measures by establishing specific requirements for the technologies used to purify kitchen exhaust. It mandates that systems like electrostatic precipitators must achieve a particular efficiency level, ensuring that emissions are significantly minimized before they impact the urban atmosphere.

This law focuses on new cookstoves, particularly those using solid fuels like wood or anthracite coal. This law also emphasizes the reduction of particulate emissions but extends its coverage to include new technologies and cooking methods not previously regulated:

- Control Device Installation: New cook stoves must include an emissions control device—such as a wet scrubber, ESP, or air filtration device—that reduces total particulate matter emissions by at least 75%. These devices must meet specific standards, including UL 1978 for scrubbers and air filtration devices, and UL 867 or 710 for ESPs.

- Operational Guidelines and Testing: Both field and laboratory testing are required to ensure that these devices meet the necessary emission reduction standards. Tests must demonstrate that the installed devices can maintain the needed efficiency under peak load conditions.

Cadexair’s Electrostatic Precipitator: A Compliance Powerhouse

Cadexair, a leader in kitchen ventilation technology, has developed sophisticated electrostatic precipitator (ESP) systems that exemplify efficiency and innovation in air purification. These systems are pivotal for commercial kitchens, particularly in urban environments like New York City, where compliance with stringent environmental regulations is crucial.

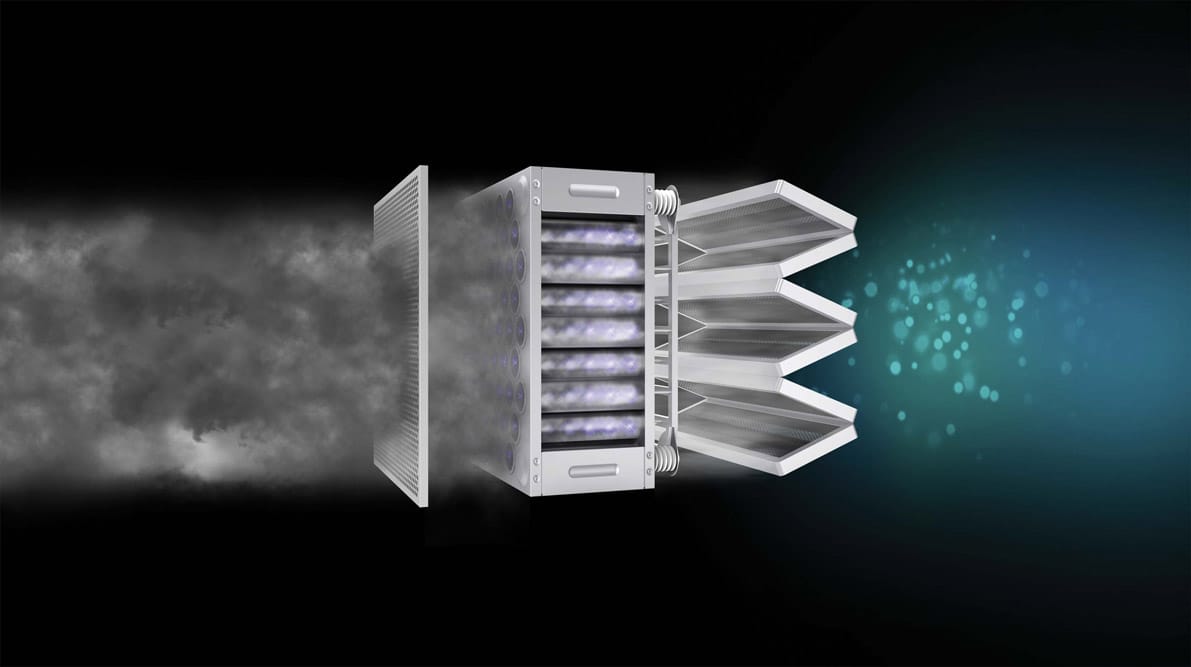

The principle behind an ESP is fascinating yet straightforward: it uses electrical forces to charge and then capture grease, smoke, and other particles as air passes through. This not only drastically reduces the emissions vented into the atmosphere but also enhances fire safety by lowering the buildup of flammable materials in exhaust systems.

High-Efficiency Particle Filtration

Cadexair’s electrostatic air cleaners boast an impressive capability to filter over 95% of particles, including those as small as 1 micron. This level of filtration is critical for reducing airborne grease, smoke, and other particulate matter that can degrade air quality and pose health risks. The efficiency of these systems is validated against rigorous standards such as UL867 and complies with NFPA96, NFPA90A, and NFPA90B, ensuring that they meet both safety and environmental benchmarks.

Operational Excellence and Seamless Integration

Designed to integrate seamlessly into any kitchen’s existing setup, Cadexair’s ESPs ensure that even kitchens in densely populated or tightly confined spaces can achieve optimal air quality without significant structural changes. This adaptability makes it a preferred choice for establishments looking to upgrade their ventilation systems without extensive renovations.

Detailed Benefits of Electrostatic Precipitators for Urban Kitchens

- Enhanced Air Quality: Cadexair’s ESPs improve indoor air quality by efficiently capturing grease and smoke. This makes the kitchen environment safer and more comfortable for staff and patrons and ensures compliance with health standards.

- Fire Safety and Compliance: By significantly reducing grease buildup, these systems lower the risk of kitchen fires, a prevalent hazard in high-volume cooking environments. Compliance with New York’s rigorous environmental standards is streamlined through the use of ESPs, which directly address the city’s pollution control requirements.

- Cost-Effectiveness and Energy Efficiency: Cadexair’s ESPs are engineered to be low maintenance and energy-efficient. They operate with a very low static pressure drop, reducing the need for high-energy consumption fans. This energy efficiency, coupled with reduced cleaning and maintenance requirements, offers substantial financial benefits over time.

- Power Efficiency: The ESP units include a high-voltage digital power supply that targets grease particles specifically, enhancing energy efficiency. This selective targeting ensures optimal filtration efficiency despite fluctuations in system variables like the type of food cooked or the volume of air extracted.

- Innovative Filter Design: Cadexair’s ESP technology’s hallmark cylindrical honeycomb cell filter is designed for maximum filtration efficiency. This design increases the particle capture rate and ensures uniform electrostatic intensity across the filter, enhancing its effectiveness and longevity.

Introducing the Stadium Hood: Tailored for Urban Challenges

In addition to the Electrostatic Precipitator, Cadexair’s Stadium Hood represents another bespoke solution, engineered specifically for kitchens operating in constrained spaces or densely populated areas such as high-rise buildings and busy neighborhoods.

This innovative hood is compact and robust, encapsulating advanced filtration technology in a space-saving design that stands just 30 inches high. With automatic fire shutters and a comprehensive fire protection system, the Stadium Hood enhances safety while maintaining operational efficiency in even the most challenging environments.

Key Features and Enhanced Benefits of the Stadium Hood

- Space Efficiency: The Stadium Hood excels in environments where space is premium. Despite its compact height of 30 inches, it houses a powerful filtration system that does not compromise on performance. This makes it ideal for urban settings where every inch of kitchen space is valuable.

- Advanced Fire Safety: Integrated with a factory-installed fire suppression system, the Stadium Hood dramatically mitigates the fire risk, a prevalent concern in high-volume cooking areas. The hood’s built-in fire protection system is designed to limit the spread of fire, providing an essential safety feature for urban kitchens.

- Operational Cost Savings: The Stadium Hood is designed to significantly lower installation costs. It operates quieter than traditional units, which enhances the kitchen work environment and contributes to a better overall atmosphere for staff and patrons. The design also allows easy access from the front, simplifying maintenance and servicing and further reducing long-term operational costs.

- Reduced Duct Maintenance: Thanks to its ingenious design, the Stadium Hood considerably lowers the frequency and cost of duct servicing. Facilitating easier access for maintenance from the front ensures that systems can be kept in top condition without the extensive downtime or labor typically required.

- Modular Configuration: The flexibility in configuration based on the exhaust air flow and the position of the filtration plenum (either in front or on top) allows for tailored solutions to fit specific kitchen layouts and needs.

Complying With Industry Standards

The Stadium Hood meets and exceeds the rigorous requirements set by standards such as UL710 and ULC-S646, ensuring that it not only provides superior performance but also adheres to the industry’s highest safety and quality benchmarks.

Ideal for Diverse Kitchen Environments

Whether for a small café or a large restaurant in a bustling city center, the Stadium Hood’s versatile and efficient design makes it suitable for a variety of culinary settings. Its ability to handle different exhaust air volumes efficiently, combined with optional features like the Cadexair D-Tech variable flow system and customized odor treatment solutions, ensures that every kitchen can achieve optimal air quality and comply with environmental standards.

The Combined Impact of Cadexair’s Technologies

Integrating Cadexair’s ESPs and Stadium hoods into kitchens represents a comprehensive approach to meeting New York’s stringent environmental standards. These systems ensure compliance with pollution control mandates and support restaurant operators in enhancing their operational efficiency and safety protocols. Adopting such technologies signifies a shift towards more responsible and sustainable culinary practices in one of the world’s most vibrant urban landscapes.

Embracing the Future of Kitchen Ventilation

For New York’s restaurants, adapting to advanced technologies like electrostatic precipitators and specialized hoods means adhering to legal requirements and embracing a leadership role in environmental stewardship. Cadexair continues to innovate, providing solutions that meet these needs while setting new standards for safety, efficiency, and environmental responsibility in the food service industry.

As New York City continues to tighten its environmental regulations, the role of technologies like those offered by Cadexair will become increasingly crucial. Restaurants looking to thrive in this new regulatory landscape will find invaluable partners in solutions that combine compliance with cutting-edge efficiency and safety enhancements.